News

01-03-2021

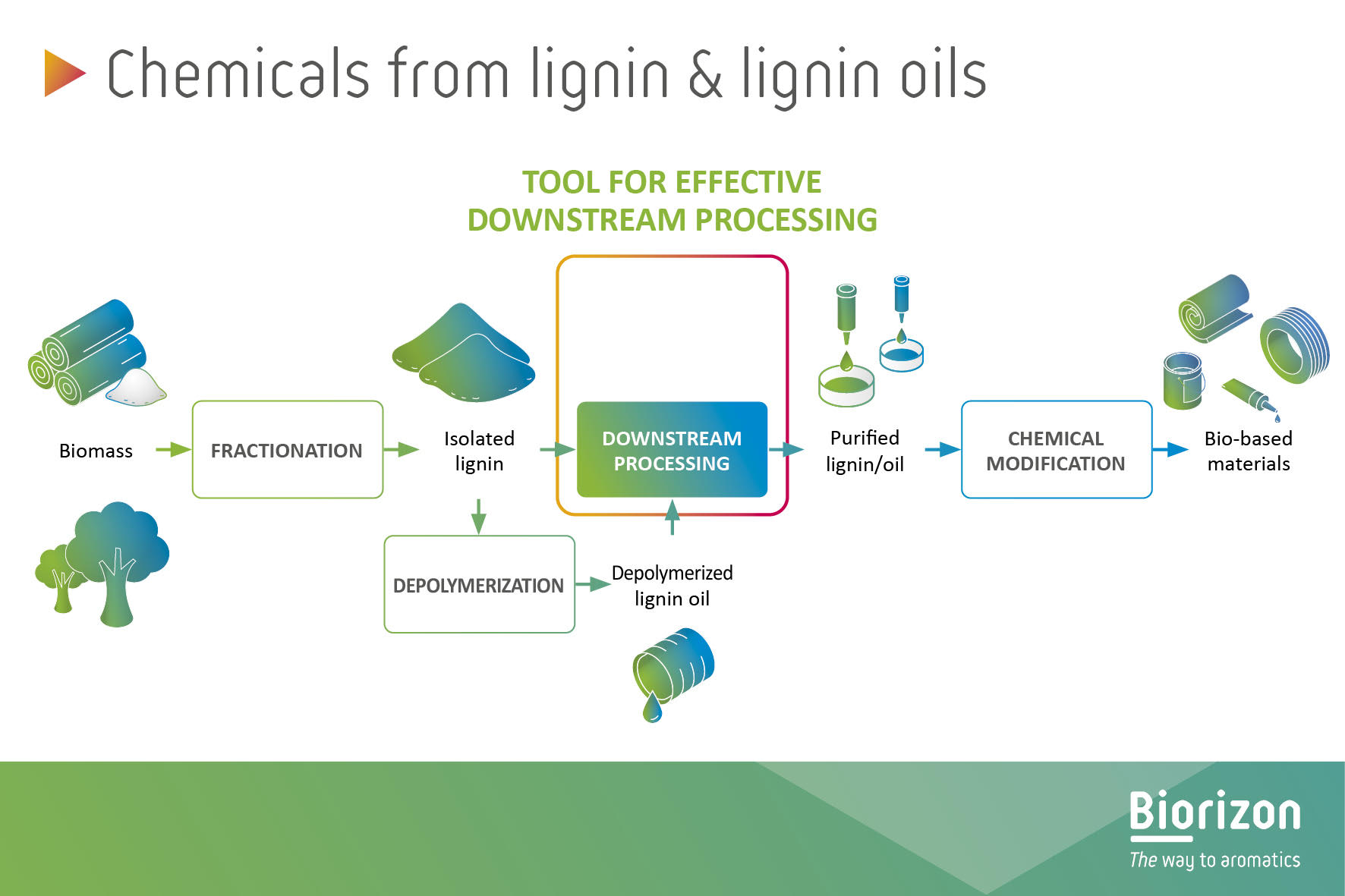

Chemicals from lignin and lignin oils: a tool for effective downstream processing

Do you wish to obtain specific properties from lignin to apply this renewable feedstock in applications such as coatings, adhesives or insulation foam? Or are you a lignin provider that struggles to find a suitable application because your lignin does not possess the right properties? Biorizon co-initiator VITO launches a tool for effective downstream processing of lignin and derived oils that is specifically designed to help you to overcome these challenges.

Downstream processing of lignin (oils) requires a perfectly aligned series of steps

Lignin is the second most abundant organic substance in plants. It constitutes 30% of the non-fossil organic carbon in the world and it is the natural raw material with the greatest content of aromatic components. No wonder lignin is often called ‘brown gold’.

However, choosing the right downstream processing strategy for lignin (oils) to end up with exactly the right specifications for specific applications can be a hard and time-consuming process. Polymeric lignin is known for its structural complexity and heterogeneity, due to the variability of both biomass sources and isolation processes. Besides its polymeric form, lignin oils obtained after depolymerization might also need different processing steps, like fractionation or purification to remove impurities such as ash or polysaccharides.

The whole process should be a perfectly aligned series of steps. But, based on the properties of the feedstock and the required end specifications, how do you decide which series of downstream processing decisions will get you the results you want?

Chemicals from lignin and oils: a tool for effective downstream processing

Biorizon co-initiator VITO has bundled decades of research and expertise in a tool that makes this process more effective and efficient. This tool is a decision tree for the selection of the appropriate downstream processing strategy for lignins and depolymerized lignin oils in order to meet the required specifications for applications. This tool is specifically designed for:

- Providers of lignin (oil) that want to align the properties of their feedstock with the requirements of specific applications;

- End users that want to adjust the properties of lignin (oil) in order it to use it in their applications, such as coatings, adhesives, sealants or elastomers.

The chemicals from lignin tool helps to navigate from the initial lignin (oil) properties to the desired application properties, selecting the best downstream processing strategy.

Example: remove polysaccharide residues to enhance lignin quality

The utilization of biorefinery lignins as renewable resource for the production of bio-based chemicals and materials remains a challenge because of their high polysaccharide content, which usually varies from 5 to 30 % by weight. The polysaccharide residues can have a major effect on lignin properties such as solubility or reactivity. Therefore, the removal of polysaccharides from lignin is an important step to enhance lignin quality and its potential application scope.

Contact

If you want more information about this tool, please contact Biorizon's Lignin Horizon Manager Karolien Vanbroekhoven at karolien.vanbroekhoven@vito.be or +32 (0)4 93 51 42 70 or Roel Vleeschouwers, Business Development Manager, at roel.vleeschouwers@vito.be.

Acknowledgement

This work was supported by the Catalisti ICON project (HBC.2018.0481) BIORESAL (BIO-based RESins from Aldehydes and Lignin), funded by Flanders Innovation & Entrepreneurship (VLAIO).