Thanks to Biorizon’s high-quality facilities, specialized knowledge, years of experience and the successful involvement of the entire bio-aromatics value chain, we manage to produce bio-aromatics continuously (on a kg/h scale). We are currently validating our continuous processes and working with industry partners toward the next stage: demonstration. This makes Shared Research Center Biorizon the most advanced and valued research program in sustainable bio-aromatics worldwide. We offer the chemical industry an excellent platform to make the transition to a circular bio-economy.

Do you want to contribute to our mission to enable commercial production of bio-aromatics by 2025? Come and join us! Take a look at the Biorizon projects for inspiration, and reach out to our business development managers for more information.

01-10-2023 - 30-09-2026 /

Bergen op Zoom

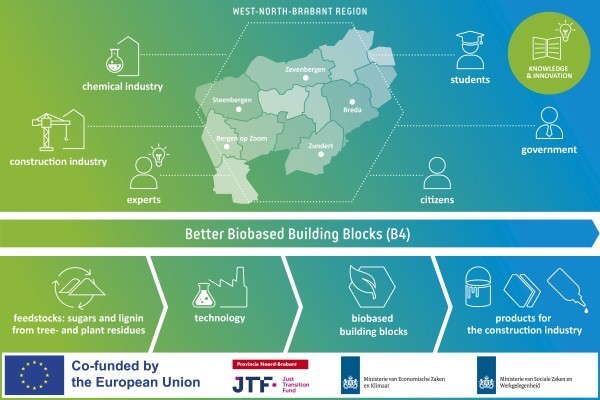

B4: Better Biobased Building Blocks

Over the next 3 years, 11 partners in West-North Brabant, led by TNO, will be working together to make green building blocks with local vegetable waste streams. From grass to glue, from sugar beet pulp to paint or from wood chips to insulation foam are examples of what the B4 project – Better Biobased Building Blocks - envisions. These building blocks not only make products for the construction industry more sustainable, but also provide scratch resistance, flame retardancy or UV resistance. Besides these technological innovations, the partners in this B4 project also share knowledge with students, companies and governments to prepare them for and involve them in this raw material transition. This will transform Western North Brabant into a hotspot for biobased building blocks for the construction industry.

15-06-2023 - 14-06-2026

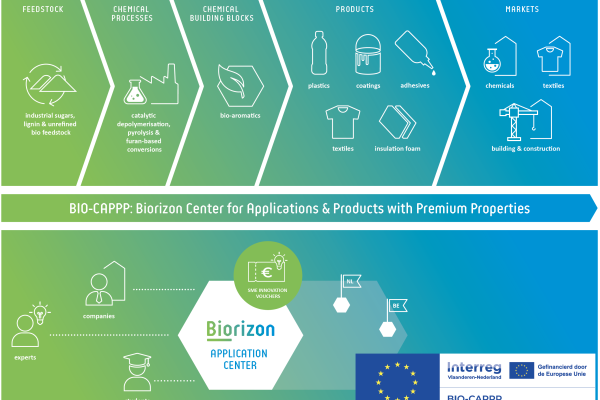

BIO-CAPPP: Biorizon Center for Applications & Products with Premium Properties

In June 2023, six partners from Flanders and the Netherlands started the BIO-CAPPP project. Over the next 3 years, together with companies, experts and students, they will develop sustainable chemical building blocks and apply them in products for the construction and textile sectors, among others. The application of these bio-aromatics not only makes the products more sustainable, but also provides premium properties. In this way, BIO-CAPPP contributes to the transition to a circular economy. The project has a total budget of €4.3 million and is co-funded by Interreg Flanders-Netherlands, VLAIO, the provinces of Antwerp, East-Flanders and North Brabant and the Dutch Ministry of Economic Affairs and Climate Policy.

01-04-2023 - 30-03-2026 /

The Netherlands

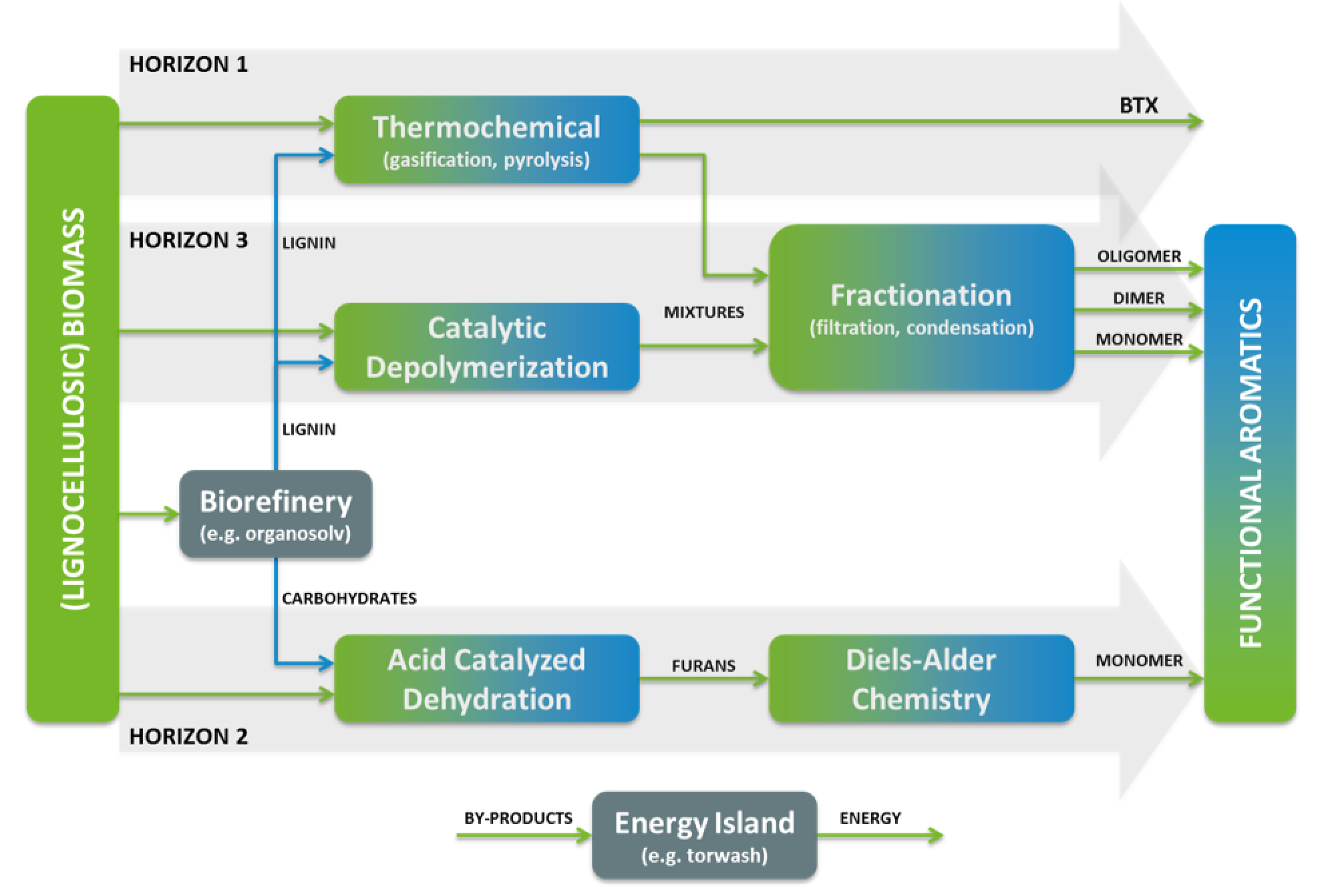

AROMATICS: Aromatic Renewables as an Opportunity for Materials with Improved Circularity and Sustainability

Fourteen partners join forces in the AROMATICS project, which stands for Aromatic Renewables as an Opportunity for Materials with Improved Circularity and Sustainability. They aim to reduce the dependence of the existing value chain on fossil-derived aromatic chemicals; from the chemical industry up to brand owners. The project partners will accomplish this by developing processes to produce aromatics from renewable feedstock. This 3-year project is performed with MOOI-funding from the Dutch Ministry of Economic Affairs & Climate.

01-01-2023 - 12-07-2027 /

Flanders

PROMIS Project: sustainable PROduction of bio-based Multi-reactive ISocyanates

PROMIS will help the chemicals and materials industries in the production of more sustainable polyurethanes (PUs). Using inventive organic chemistry and catalysis, novel bio-based PU building blocks, called isocyanates, will be designed. As a result, current challenges in polyurethane industry will be addressed through closely interlinked valorisation goals.

01-01-2023 - 12-07-2027 /

Flanders

DELICARE Project: DEpolymerisation of hydrolysis LIgnin for Conversion to Acrylic REsins

The DELICARE project maximally exploits the potential of hydrolysis lignin (HL) as a sustainable source of reactive bio-aromatic compounds. Using a catalytic depolymerization we target applications in acrylic resins. DELICARE will link upstream HL producers and downstream acrylic resins and polymer stakeholders, resulting in an optimized value chain, new economic opportunities and new synergetic partnerships.

01-10-2021 - 31-12-2022

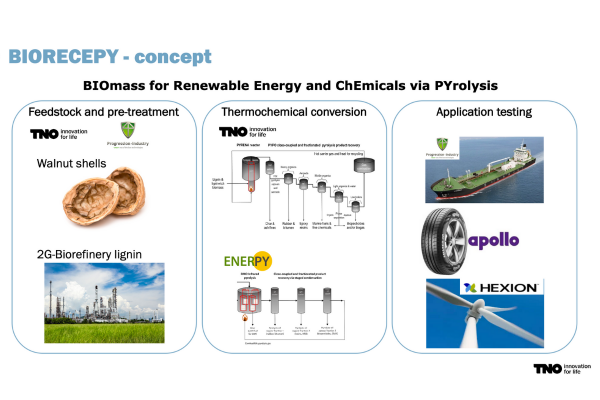

BIORECEPY project: Biomass for renewable energy and chemicals via pyrolysis

Biorizon co-initiator TNO and partners have recently started the BIORECEPY project to embark on extended bio-aromatics application development with the industry. Tires, epoxy resins and fuels will be developed out of lignin and lignin-rich biomass, using thermochemical conversion technologies.