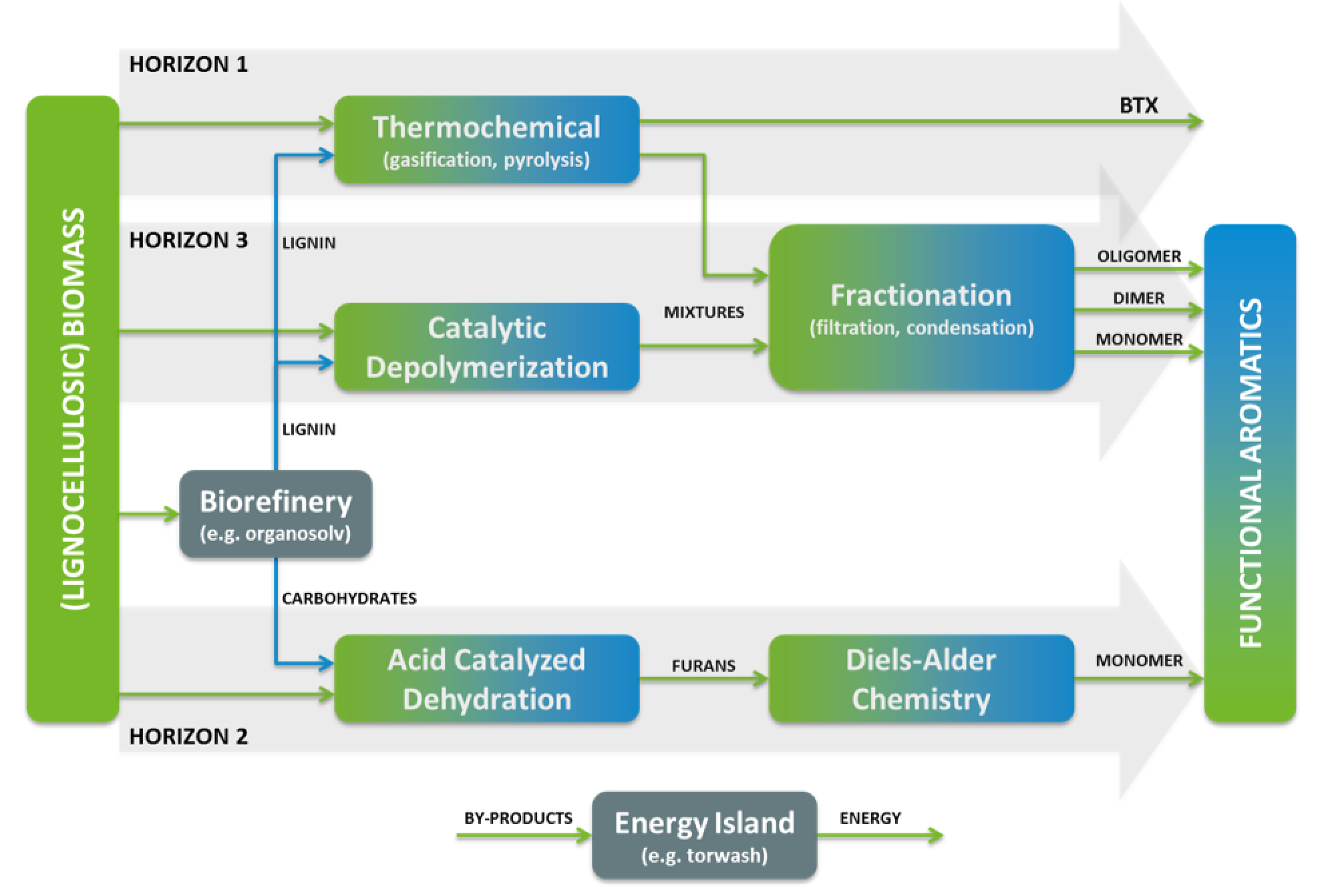

To achieve our mission – enabling the commercial production of bio-aromatics by 2025 – Biorizon has developed three program lines or “Horizons” in which industrial partners can participate:

- Horizon I focuses on thermochemical processes

- Horizon II focuses on sugar/furan technology

- Horizon III focuses on lignin technology

More information

If you share our ambition and want to collaborate with our Shared Research Center, please join our community, visit the Biorizon headquarters at the Green Chemistry Campus in Bergen op Zoom (NL) or reach out to our business development managers.