Projects

07-03-2021 - 31-12-2022 /

Green Chemistry Campus - Bergen op Zoom, the Netherlands

PRIMA-2 Project: Pyrolysis-based Recycling Initiative for MDF Waste

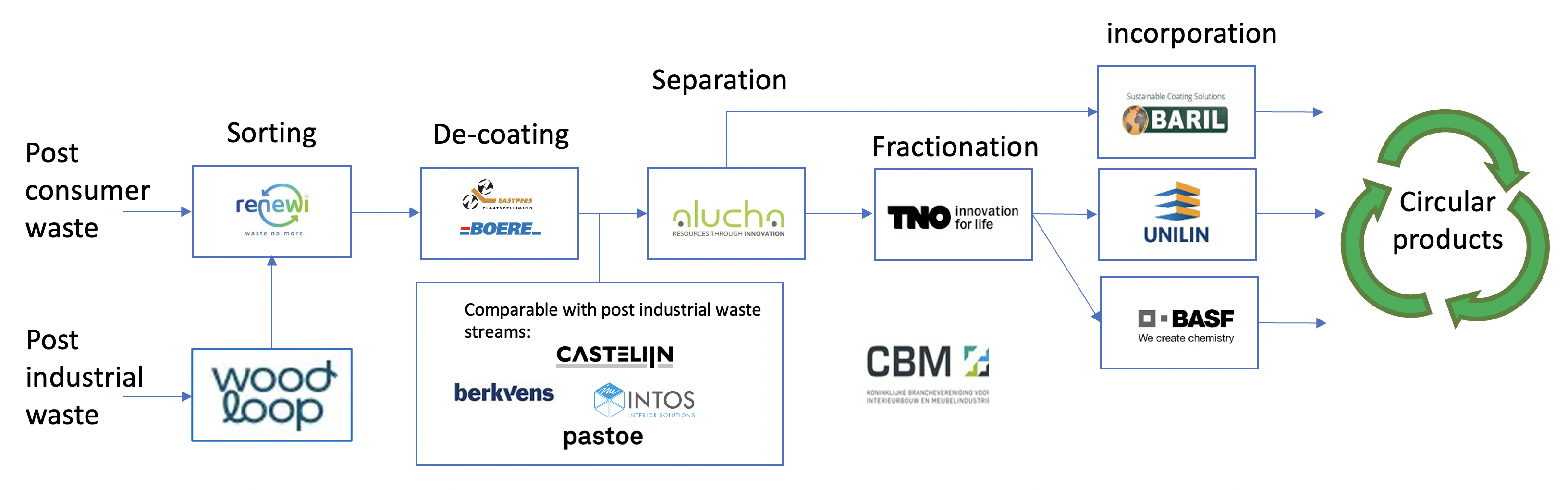

Biorizon co-initiator TNO embarked on a project focused on the valorisation of waste wood from the furniture industry, MDF in particular. In the project, led by the Dutch interbranche organisation for the furniture industry CBM, partners over the entire value chain for furniture plate material are involved to develop new (chemical) recycling options as an alternative to combustion in waste incinerators.

The project is aimed at maximum recovery of high-value circular materials. Project partner Renewi selectively collects the different waste wood streams from the furniture industry, including wood dust and (MDF) plate material. The plate material then undergoes a pre-separation treatment by a grinding and detection technology developed by the company Boere. The clean core and/or underlayer is sent back to Renewi to be shredded and applied directly in the chipboard industry. The mineral-rich top and bottom sides are pyrolyzed together with the wood dust by technology start-up Alucha. The TNO technology of vapour fractionation by staged condensation is applied to obtain different valuable fractions from the pyrolysis vapour. This includes melamine to be applied by BASF as well as methyl methacrylate and phenols (for the production of formaldehyde resins) to be applied in formaldehyde resins by Unilin. Furthermore, Alucha will investigate the potential of the retrieval of a TiO2-rich mineral fraction to be applied as circular pigment by Baril Coatings.

In the project, TNO will first conduct exploratory trials at lab-scale and in their pyrolysis-staged condensation process development unit at the Green Chemistry Campus in Bergen op Zoom. Then, the fractionation by staged condensation concept will also be applied at the Alucha pyrolysis pilot in Cuijk. The samples produced by both TNO’s and Alucha’s processes will be utilized in application development work by Baril Coatings, BASF and Unilin. Moreover, TNO will conduct a Life Cycle Assessment in order to evaluate these novel circular value chains and the respective CO2 emission savings.

More information

If you want to know more about this project, or the potential of bio-aromatics in your application, please contact Biorizon’s Thermochemical Horizon Manager Jaap Kiel at jaap.kiel@tno.nl or +31 (0) 6 26 43 49 26.

Acknowledgements

This project is co-funded by the Netherlands Ministry of Economic Affairs and Climate through the Netherlands Enterprise Agency RVO with reference number DEI221016.