News

08-10-2020

TNO brings PYRENA-PYPO pyrolysis equipment to Green Chemistry Campus’ demo facility

There it is! The long-awaited PYRENA-PYPO installation has arrived at Biorizon's headquarters at the Green Chemistry Campus in Bergen op Zoom. With this highly advanced pyrolysis equipment, TNO's Energy Transition Unit will produce samples of bio-aromatics that will be tested in applications such as bitumen, rubber, marine fuels and resins.

Bio-Aromatics: Impactful Green Alternative for Chemical Industry

Shared Research Center Biorizon, an initiative of TNO and VITO, has been co-creating technologies for the production of bio-aromatics at the Green Chemistry Campus in Bergen op Zoom since 2013. Together with industrial partners, Biorizon creates and develops innovative chemical processes for the production of renewable aromatics from residual biomass.

Aromatics are important building blocks for the chemical industry: no less than 40% of chemicals are aromatic, and they bring essential functionalities such as durability and thermal and UV stability to products like plastics, resins and coatings. Bio-aromatics provide new functionalities and an impactful and green alternative for current petrochemical products that are difficult to re-use or recycle, including paints, adhesives and lubricants. Biorizon’s aim is to enable commercial production of bio-aromatic building blocks by 2025.

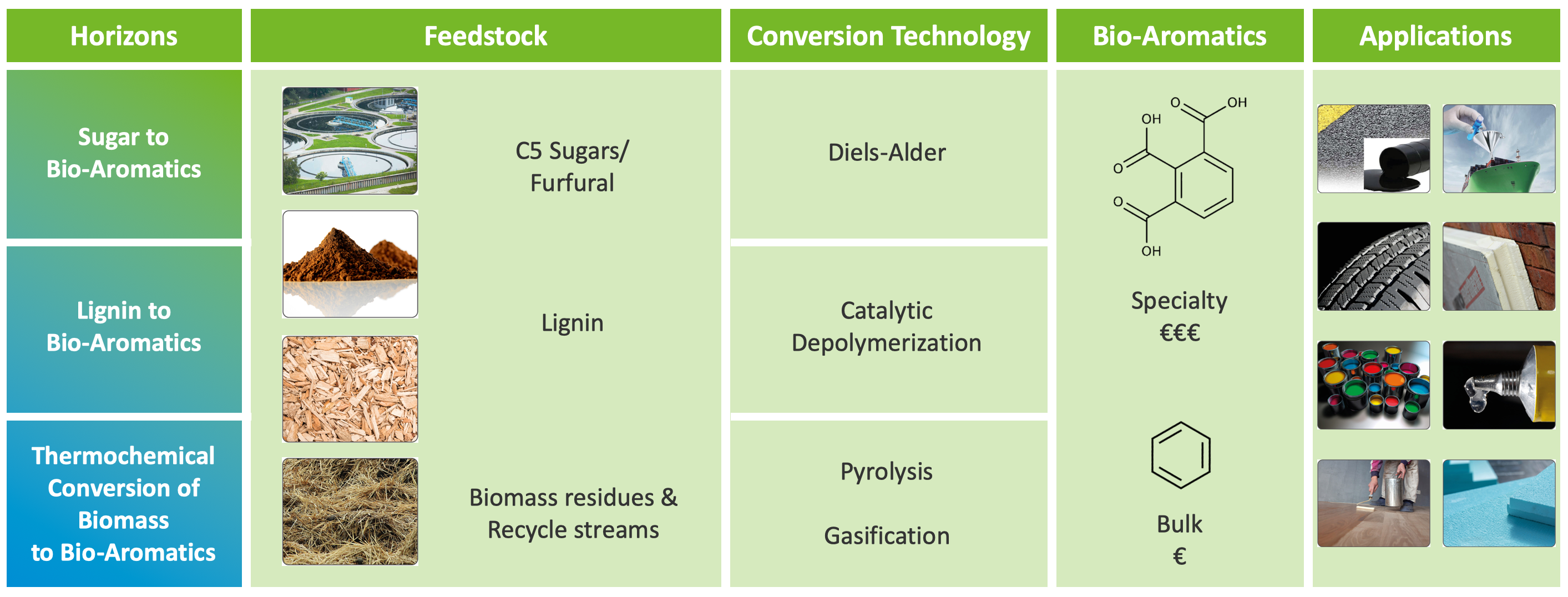

Biorizon’s Thermochemical Conversion of Biomass to Bio-Aromatics Horizon

TNO’s Energy Transition Unit (former ECN) is responsible for Biorizon’s Thermochemical Conversion of Biomass to Bio-Aromatics Horizon. Starting from lignin or lignin-rich feedstocks, the overarching goal is to thermally depolymerize the material via pyrolysis and recover the pyrolysis vapours in a limited number of fractions that can be deployed as biobased additives for applications such as bitumen, rubber, marine fuels, resins and as feedstock for extracting high-value bio-aromatics.

PYRENA-PYPO: Continuous Pyrolysis Pilot for Biobased Additives & Aromatics

TNO has been developing various in-house technologies, such as FABIOLA for innovative fractionation of lignocellulosic biomass and PYRENA-PYPO, pyrolysis for renewable aromatics with closely coupled pyrolysis product obtention. The PYRENA-PYPO equipment will be installed in the demo facility of the Campus to produce test samples for industrial application. It’s a continuous pyrolysis pilot unit consisting of a 5-10 kg/h (input basis) pyrolyzer, PYRENA, with a closely coupled unit PYPO for fractionated recovery of the pyrolysis vapours. The technology uses an innovative downstream cascade approach to obtain different fractions with high potential for applications regarding biofuels and biobased materials. Furthermore, all the surrounding analytical equipment will be installed to characterize the full process chain, from feedstocks to products.

Contact Information

If you want to discuss the thermochemical conversion of biomass to bio-aromatics, please contact Biorefinery & Upscaling Consultant Biomass & Energy Efficiency Sergio Rios via +31 (0) 61 539 88 41 or sergio.rios@tno.nl.