News

05-10-2021

LIGNICOAT project: Sustainable COATings based on LIGNIn resins and bio-additives with improved fire, corrosion and biological resistance

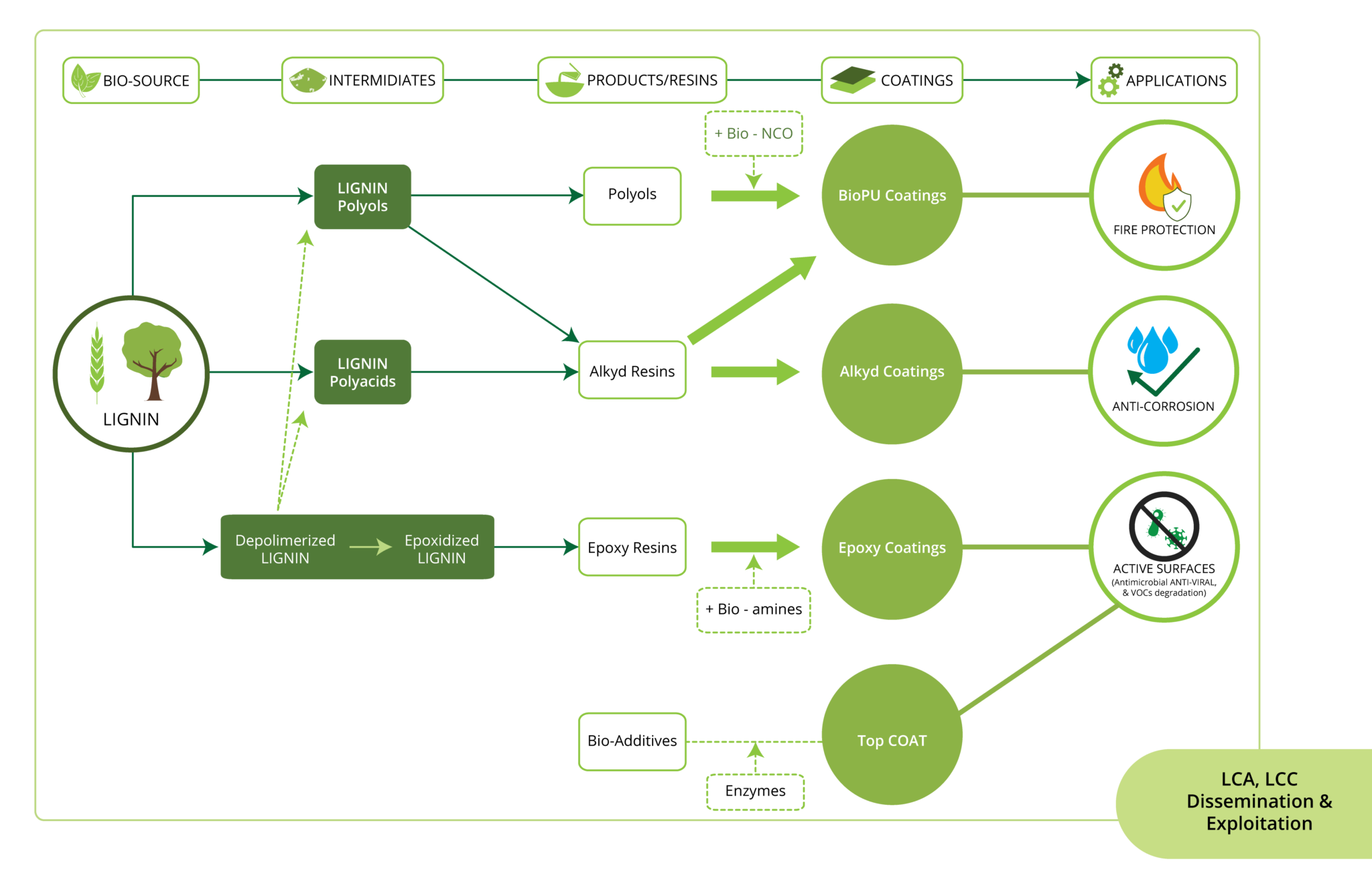

Biorizon co-initiator VITO is partner in the LIGNICOAT project that aims to demonstrate technical and economic feasibility of the use of lignin as raw material to produce bio-resins for different applications in the field of functional coatings.

VITO’s role in the project is to:

- Apply reductive catalytic depolymerization to lignin to obtain fractions that meet the required technical specifications for resin manufacturing and application development.

- Introduce epoxy groups in lignin (oils) and optimize formulation of epoxy resins.

- Apply membrane technology to recover, fractionate and purify lignin polyacids.

About LIGNICOAT

Sustainability in coatings covers aspects related to energy and resource conservation, waste minimization or efficiency and the use of renewable and non-toxic products. The coatings industry has been driven by regulatory issues to diminish the content of volatile organic compounds to improve indoor and outdoor air quality, shifting from solvent borne systems (still the preferred choice globally) to waterborne ones.

Sustainability in coatings covers aspects related to energy and resource conservation, waste minimization or efficiency and the use of renewable and non-toxic products. The coatings industry has been driven by regulatory issues to diminish the content of volatile organic compounds to improve indoor and outdoor air quality, shifting from solvent borne systems (still the preferred choice globally) to waterborne ones.

However, even in the case of products labelled as ‘environmentally friendly’ their bio-based content is usually small (up to 30-40%). The challenge is to substitute fossil-based resins maintaining at least the same performance. New bio-based value chains are necessary.

Lignin is an underutilized product with a high potential to provide not only economic returns, but also environmental benefits if value-added applications are found. Although lignin is a topic of great interest, the conversion of lignocellulosic biomass into real products is not trivial and still no commercial options are available.

LIGNICOAT aims to provide new synthetic routes to obtain bioresins ‘à la carte’ (PUD, ALKYD and EPOXY) based on lignin intermediates (Polyols, Epoxies, phosphorylated, polyacids and carbonates) for application in coatings and validated in an industrial relevant environment (TRL5). The target is not only to increase the biobased content and ensure performance, but also take advantage of lignin specific characteristics, to develop bio-additives (enzymes, chitosan, sugars, …), increasing the bio-content and providing anticorrosive, fireproof and antimicrobial/antiviral features in high-volume market case studies. Depending on the intermediates and the resins used, the estimated bio-content of the coatings will vary between 60-90%.LIGNICOAT consortium

The multidisciplinary and complementary consortium consists of 9 industrial partners:

BARPIMO, VENCOREX, AEP, HEXION, FORESA, BRS, IRIS, ECOAT and AXIA and 4 RTOs, TECNALIA, VITO, VTT, NORCE and ARDITEC.

- Duration: 2021 – 2024

- Total budget: € 5.233.801,25

Acknowledgements

The LIGNICOAT project has received funding from the Bio-Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under the Grant Agreement No. 101023342.

The LIGNICOAT project has received funding from the Bio-Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under the Grant Agreement No. 101023342.

More information

For more information on the LIGNICOAT project, please contact Viviana Polizzi, R&D professional bio-aromatics at VITO at Viviana.polizzi@vito.be.