News

28-08-2019

Call for Participation: Biobased Phthalic Anhydride

Biorizon co-initiator TNO is looking for partners that are interested in the development of biobased phthalic anhydride (PA): a key feedstock for plasticizers, as well as unsaturated polyester and alkyd resins.

In specific response to the wish of industry to develop biobased coatings, this project will be aimed at improving and expanding the scientific knowledge base to enable the scale up of biobased PA production and contribute to the development of a sustainable chemical industry.

Biorizon is looking for the following partners:

- Chemical intermediate manufacturers that are preferably already active in the PA market and would like to collaborate on technology development and the production of biobased PA;

- Resin, coating and paint manufacturers who are committed to a sustainable chemical industry and want to contribute to the pioneering development of biobased PA.

- Other relevant partners like RTO’s, public entities that want to contribute to this technology development.

Biorizon co-initiator TNO (the Netherlands organisation for applied scientific research) is the initiator of this project and is currently busy with the formation of a consortium and the search for additional funding.

Points of attention for partners:

- Participation is open to a diversified mix of organizations (RTO’s, public entities, private companies (industrial partners and SMEs), NGOs.

- Depending on the type of involvement, contribution per partner is expected to range from €25k-€50k in cash and €25k-€50k in kind.

Project aim: lay a scientific basis to enable biobased phthalic anhydride production

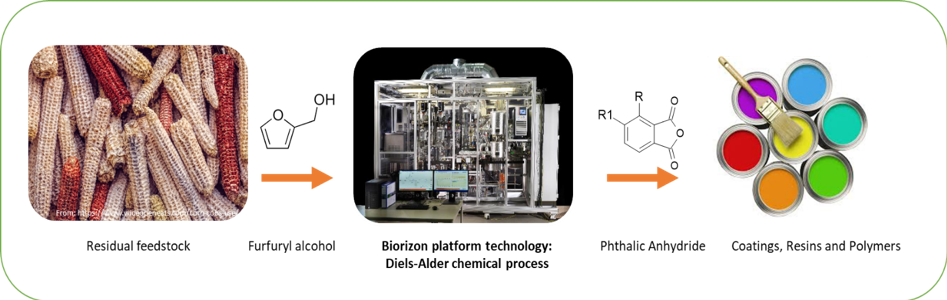

In this ‘Biobased Phthalic Anhydride’ project, the Biorizon Diels-Alder platform technology will be used for the production of biobased PA. The novel route starts from furfuryl alcohol, which is commercially available, made from residual feedstock that does not compete with food or feed crops (see figure 1). The technology route to PA is atom efficient and has been shown to work on lab scale (TRL 2/3). The information required to improve the current process and make it suitable for scalable continuous processing will be developed within this project, facilitating a fast scale-up. This will make delivery of small scale samples bio-PA possible within the project.

Figure 1. Schematic overview of the ‘Biobased Phthalic Anhydride’ Project

The pathway that will be developed within the ‘Towards Biobased PA’ project has the potential to become the most cost-efficient route towards biobased PA. Partners of this project will have the opportunity to be involved from an early stage of this promising research, including the benefits of sharing knowledge and being at the forefront of application and commercial developments.

Why Phthalic Anhydride

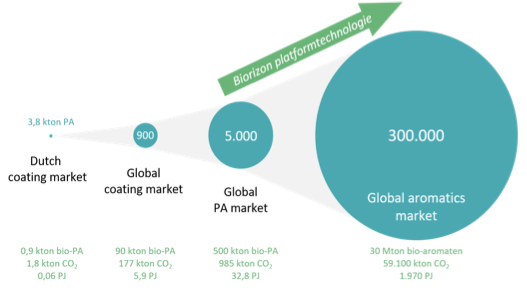

Phthalic Anhydride is one of the main aromatic building blocks that is used in plasticizers and resins. The estimated global market size for PA is around EUR 8 billion (5,000 kton of PA), with an estimated 56.5% of this being used for plasticizers and 18.1% ending up in unsaturated polyester resins. Only a 10% replacement of the petrochemical variant by biobased PA could mean reducing CO2 emissions by almost 1,000 kton globally, a significant number (see figure 2).

Figure 2. Potential sustainability impact of the Biorizon platform technology Based on Lin at al., AIChE Journal, 61(11), 3708–3718, https://doi.org/10.1002/aic.14921 and https://www.transparencymarketresearch.com/pressrelease/phthalic-anhydride.htm, consulted on 2019-07-30

Timeline

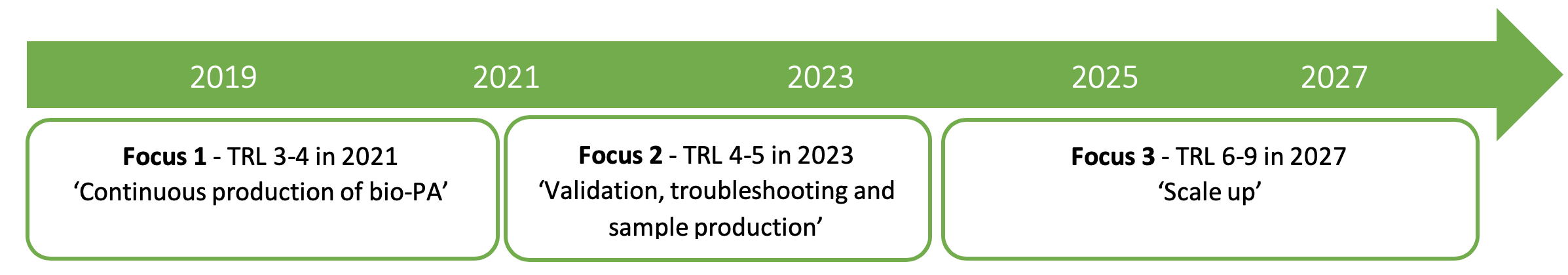

The development of the pathway to biobased PA has started and relevant partners are invited to join forces in the project ‘Bio-based Phthalic Anhydride’. The roadmap of the technology development is depicted in figure 3.

Figure 3. Roadmap of technology development for biobased PA

Figure 3. Roadmap of technology development for biobased PA

About Shared Research Center Biorizon

Biorizon is an industry driven Shared Research Center (powered by TNO, VITO, ECN part of TNO, & Green Chemistry Campus) that co-creates renewable aromatics to outperform their fossil counterparts, in sustainability as well as functionality. The Biorizon Diels-Alder platform technology converts residual biomass into functionalized aromatic building blocks for the chemical industry. This has been successfully demonstrated at bench-scale at the Green Chemistry Campus through 3 separate 1-10L continuous skids at TRL 4-5, which enable fast scale up of the technology. Next to successful efforts to make specialty chemicals with the Diels Alder platform technology, efforts are now being invested in the manufacture of biobased aromatic commodity building blocks. In this way, Biorizon wants to maximize its impact in the chemical industry.

More information

- More info on Biorizon: www.biorizon.eu

- Please join Biorizon's Community: www.biorizon.eu/community

- If you want to know more about (participating in) the Biobased PA project or Biorizon, please contact Monique Wekking via monique.wekking@tno.nl or +31 (0)6 46 84 73 58.