News

17-01-2022

Bright Coatings Project: Pre-commercial demonstration of bio-aromatic MPA in a 100% sustainable alkyd coating

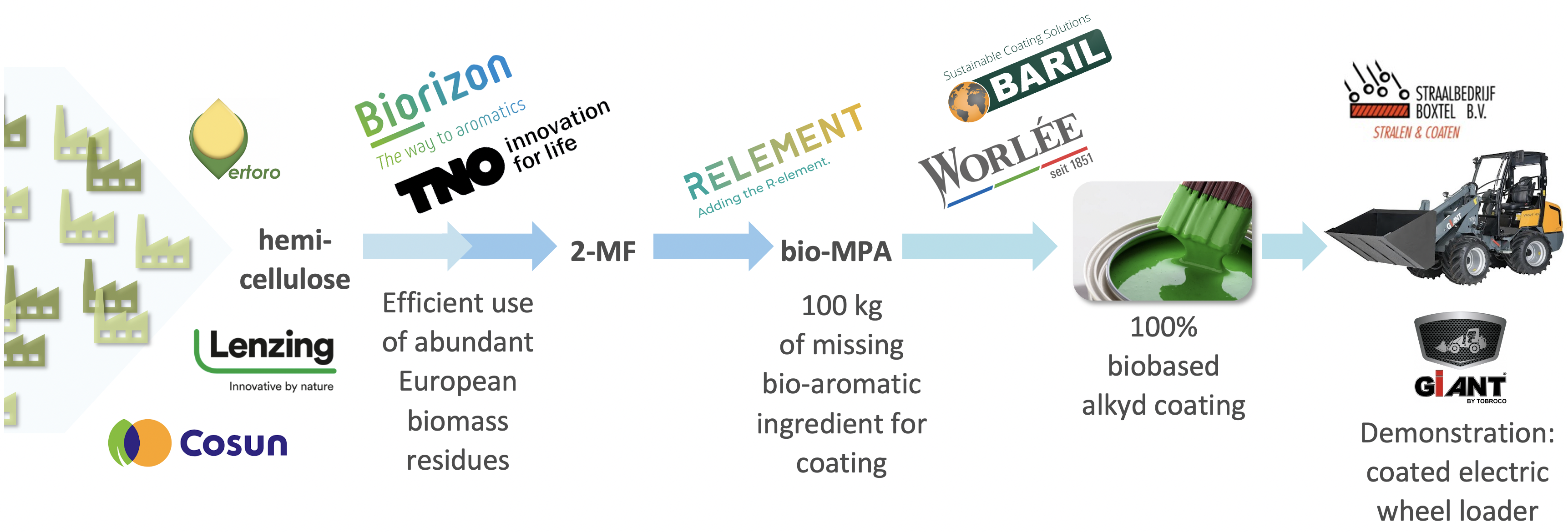

Biorizon’s spin-off company Relement is coordinator of the recently started Bright Coatings project. Biorizon co-initiator TNO participates as well. Objective of the project is the realization of a pre-commercial demonstration for the production and application of the ‘missing-link’ in a 100% sustainable alkyd coating application: the biobased aromatic MPA, based on locally available starting materials.

Missing ingredient

The coating industry is in an urgent need to lower their CO2-footprint. At end of life a coating will be burned as waste, since recycling is very difficult. This results in CO2 emission, since today coatings are predominantly made from fossil resources. Therefore, making biobased coatings is key. However, one important ingredient is missing to make a 100% sustainable coating, which is a sustainable alternative for fossil based phthalic anhydride. It is this aromatic that makes the coating glossy, scratch resistant and UV-stable.

Within the Bright Coatings project, Biorizon’s spin-off Relement will scale-up production of this missing link, the bio-aromatic MPA, towards (sub)commercial scale (>100kg), which as of today has not been done before. Subsequently, bio-aromatic MPA will be formulated in a 100% sustainable alkyd coating by Worlée and Baril Coatings. In doing so, the bio-aromatic MPA will be the first biobased aromatic product that can replace fossil phthalic anhydride in alkyd coating and that can be produced on industrial scale.

To achieve a sizable impact with this project, the full production chain for these coatings will be researched, developed, evaluated and improved upon. Finally, application of the 100% sustainable alkyd coating will be demonstrated on an electric wheel loader vehicle.

The starting material for biobased aromatic MPA is 2-methylfuran (2MF) which can be produced from locally available residual hemicellulose. For this reason, established and upcoming European biorefineries Cosun, Lenzing and Vertoro joined this consortium to align their residual hemicellulose feedstock with integrated 2MF production. Biorizon’s co-initiator TNO, which has established know-how and facilities on hemicellulose valorization via platform molecule furfural, is responsible for the technology development which allows the aligned conversion of locally sourced hemicellulose, via furfural, to 2MF.

It is expected that the Bright Coatings project will have a positive impact on the economy as well as any industry that is reliant on the use of specialty aromatics. This industry and market have been waiting for a long time for sustainable aromatic solutions to become available. Through the establishment of the aforementioned local value-chain from biomass to coatings, this project contributes to the United Nations Sustainable Development Goals such as a 55 % net CO2 emission reduction as presented under the Fit for 55 package.

For more information on this project please visit the Bright Coatings project website, contact Biorizon’s Sugar Horizon Manager Paul Könst at paul.konst@tno.nl or +31 (0) 6 25 04 13 79 or Relement CCO Monique Wekking at monique.wekking@relement.eu or +31(0)6 468 473 58.