Biorizon Innovation and Upscaling of Renewable Aromatics Technology (BIO-HArT)

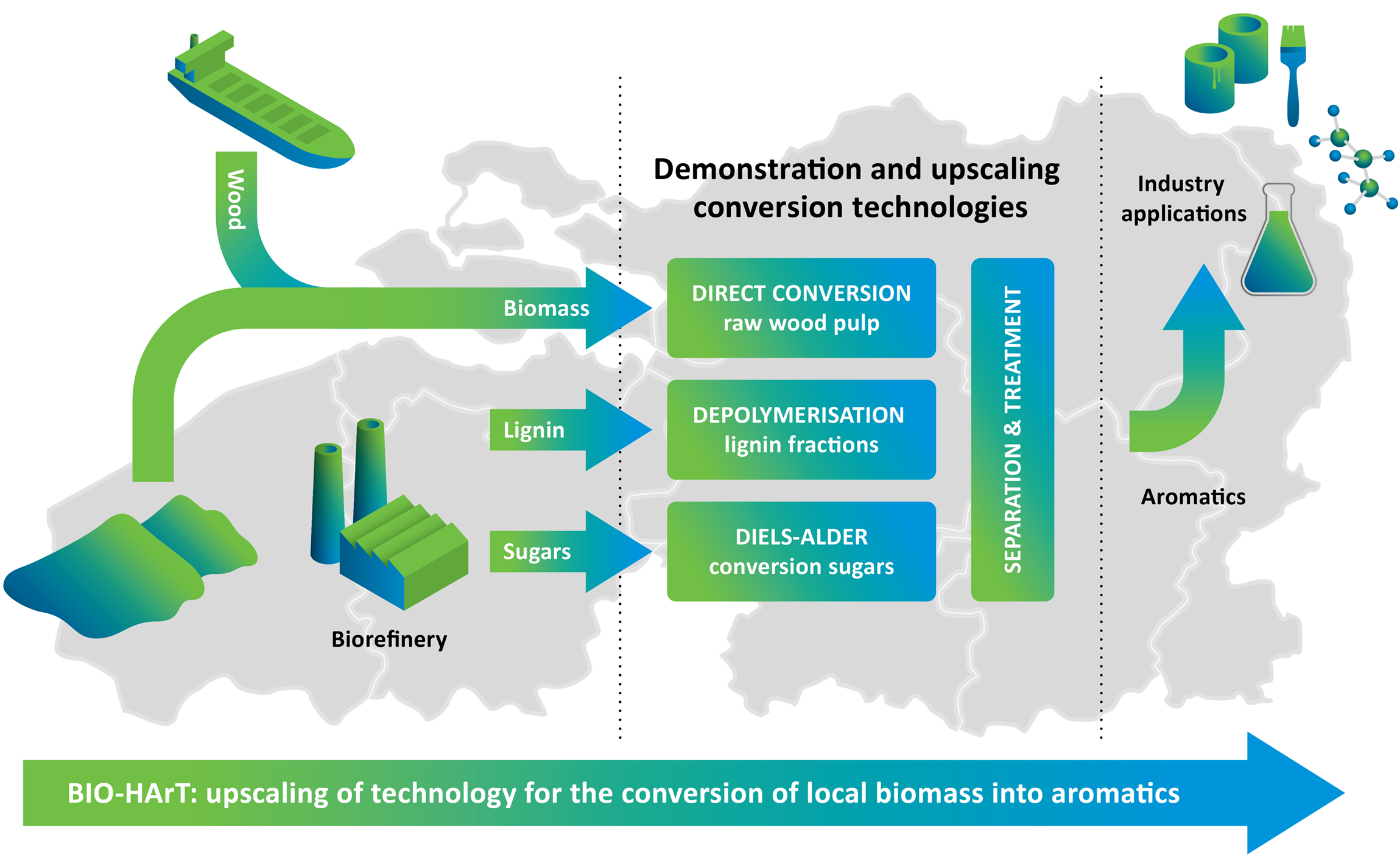

The cross-border project BIO-HArT, acronym in Dutch for “Biorizon Innovation and Upscaling of Renewable Aromatics Technology”, was set out in 2016 to scale up technology for the production of bio-aromatics from biomass, focusing specifically on woody biomass sources. By the end of 2018 this must result in functioning bench-scale demonstrators and optimized processes with which samples can be provided to the industry on a kilogram scale.

By demonstrating the technology within this project on a larger scale, the confidence in the applicability of the technology on an industrial scale increases and the risk to invest diminishes. Simultaneously bio-aromatics will be produced in sufficient quantities to be able to start application development routes.

"The BIO-HArT-project is of great importance to be able to accomplish our final goal: enable commercial production of bio-aromatics by 2025", says scientific manager of Biorizon Jan Harm Urbanus.

A visual impression of the BIO-HArT project

Consortium of 10 partners

A consortium of 10 partners from industry and research organizations is working on the realization of these ambitious targets.

Mid-term results

By mid 2017 several key milestones have been achieved illustrating already some of the successes of BIO-HArT:

- Protocols are established for bio-refining of several raw materials like Miscanthus, corn straw, flaxstraw, into sugars and lignin.

- Protocols (reaction conditions, processes, etc.) have been established and optimized for the conversion of wood, lignin and sugar fractions into target aromatic compounds.

- Pilot installations have been established along the complete chain for the bio-refinery of biomass, conversion and fractionation of obtained lignin and sugar fractions to aromatic compounds, in specific the following installations:

- 4 pilot installations for the bio-refining of lignocellulosic materials into sugars and lignin.

- A 2L reactor for the direct catalytic conversion of wood to a mixture of alkylfenols (the so-called “Lignin-first” technology). This reactor will be used to further optimize the reaction on kg scale and for the delivery of samples for evaluation in application.

- Two continuous process installations that perform several of the key reactions in the Diels-Alder approach from sugar based starting materials (Furans) towards aromatic compounds. BIO-HArT is now able to meet requests from companies for samples on multi-kg scale.

- A mini-pilot for a mobile nano-filtration unit for the 1) fractionation / purification of the alkylfenol mixture from the Lignin-first process and 2) the fractionation from the Crude Lignin Oil obtained from a catalytic depolymerization process. - Samples of several aromatic compounds / fractions have been provided on 100g – 1kg scale for evaluation of their quality in a range of applications like coatings, resins, adhesives, lubricants, polyesters, and polyurethane applications.

Furthermore, the following news articles were published on the BIO-HArT project:

- Biorizon presents virtual reality model of demonstrator for bio-aromatics

- Call for participation BIO-HArT: test bio-aromatics samples and discuss desired characteristics

- New insights in furanic intermediates and aromatic derivatives from biomass

Next step in industry-driven roadmap of Biorizon

This project is the next step in the industry-driven roadmap of Shared Research Center Biorizon. The BIO-HArT-project has got 3 goals:

- Development of optimized procedures for chemistry and process.

- Realization of generic and multi-purpose bench scale demonstrators for the 3 technologies (wood, sugars and lignin to aromatics).

- Producing samples of sugars, lignin, furans, akylphenols, mono-, di- & tri-acids, functionalized phenols and other aromatic compounds. Subsequently, together with the industry applications will be developed on the basis of these samples.

Together with the industry the project results of BIO-HArT will be further developed and eventually they will be implemented in new value chains in which multiple feedstock suppliers, chemical companies and end users will be incorporated and in which existing and new production locations will be used.

Cross-border cooperation following the principle of open innovation

The development and scaling up of technology for the production of bio-aromatics is a major challenge that demands a lot in terms of knowledge, experience and facilities. That's why Dutch and Flemish companies, governments and knowledge institutions bundle their strengths, both within Biorizon and the BIO-HArT project. Together they form not only a part of the Biobased Delta, but also of the world's largest chemical cluster, the ARRR cluster (Antwerp-Rotterdam-Rhine-Ruhr).

In BIO-HArT, project coordinator and co-initiator of Biorizon TNO works together with VITO (also co-initiator of Biorizon), Avantium, Chemelot InSciTe, University of Antwerp, KU Leuven, Bio Base Europe Pilot Plant, Technical University Eindhoven, Maastricht University and DSM Materials Science Center. Furthermore a close cooperation will be established with feedstock suppliers, producers and processors of aromatics, end users, knowledge and education organizations and the private sector.

The BIO-HArT bench scale demonstrators will be realized at five different locations in the border region that complement each other optimally: the Green Chemistry Campus in Bergen op Zoom, the Bio Base Europe Pilot Plant in Gent, the Brightlands Chemelot Campus in Geleen, the Chem&Tech Campus in Leuven and Blue Gate in Antwerp. The accelerated establishment of value chains within this project will give an impulse to businesses and employment in South-Netherlands and Flanders.

Profitable and sustainable prospects for the chemical industry

Aromatics are one of the main raw materials used by the chemical industry: 40% of all chemi-cals are aromatic by nature. Aromatics are currently extracted from oil, which leads to the emission of CO2. The Biorizon Shared Research Center, initiated by TNO, VITO and Green Chemistry Campus, together with partners develops technologies to extract aromatics from plant residues. This reduces dependency on oil, leads to lower CO2-emissions, and provides profitable and sustainable prospects for the chemical industry and the supply industry.

Interreg

This project is established by a contribution of the European Interreg V Flanders-The Netherlands program that stimulates innovation, sustainable energy, a healthy environment and the labor market by means of cross-border projects. On a total budget of € 6.085.445,38 Interreg contributes € 3.042.722,69 (50 %) and besides that the Dutch Ministry of Economic Affairs, the provinces of North-Brabant, Antwerp, East-Flanders and Flemish-Brabant offered additional funding. Thereby they make an important contribution to the further development of the Flemish-Dutch border region as a top location for the transition to a more sustainable, biobased economy and an efficient use of natural resources.

More information

- More info on Biorizon: www.biorizon.eu

- Please join Biorizon's Community: www.biorizon.eu/community

- If you want to know more about (participating in) the BIO-HArT-project or Biorizon, please contact Nadine Wennersbusch via nadine.wennersbusch@tno.nl or +31 (0)88 866 63 71