News

03-12-2015

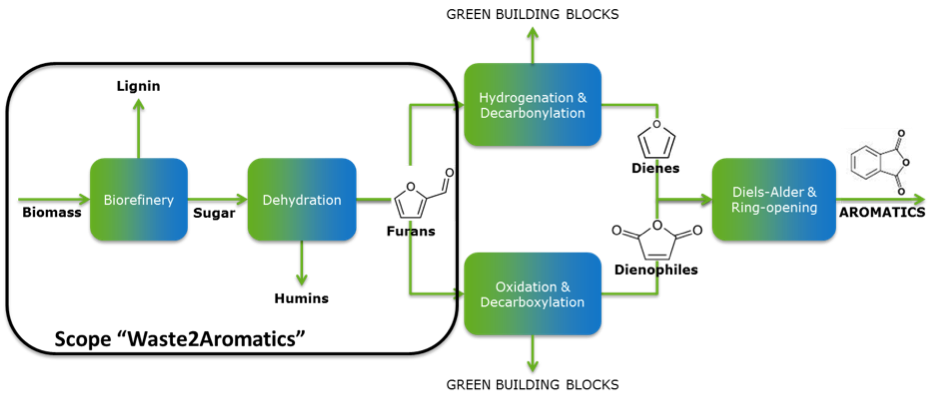

Follow-up to Biorizon’s successful Waste2Aromatics project planned

Dutch households produce a total of almost five million tons of household waste each year. The Waste2Aromatics project explored various ways of using carbohydrates (sugars) in waste streams as feedstock for the production of biobased aromatics. As one of the partners in Biorizon, TNO was involved in this project, as were Attero, AEB, Orgaworld, and the Dutch Waste Management Association. The partners’ efforts have been crowned with success. The technologies they selected proved to be highly efficient at converting sugars in waste into useful building blocks. Also – importantly – various business cases have been worked out which, according to the calculations, are very promising. This generated sufficient material and enthusiasm for a follow-up project, which is currently being developed within Biorizon’s framework.

From heterogeneous waste to aromatics, via furans

At the start of the project, nine different waste streams were selected and extensively analysed for properties that were relevant to the target technologies. Based on this analysis three waste streams (including organic waste) were selected for further study. To produce bio-aromatics from household waste, cellulose (or hemi-cellulose) contained in the organic fraction must be converted to furans. Two different techniques were used for this chemical/catalytic conversion: the Superheated steam (SHS) technology and the Bi-phasic reactor (BPR) technology.

Figure 1 As part of Biorizon’s “Sugars to Aromatics” programme line, the Waste2Aromatics project plays a crucial part in developing technology capable of supplying furans cheaply.

Result: SHS & BPR technologies are highly efficient

The technologies selected proved to be highly efficient at converting waste into furans. The experimental yields obtained in this project ranged from 10% to 45% for HMF, from 50% to 80% for furfural, and from 60% to 70% for levulinic acid. These results alone are very promising, yet there is plenty of potential for further improvement.

Figure 2 Simplified overview of flowchart

Business cases: very positive

These positive results provided a basis for the business case analyses that were carried out. A mathematical model has been used to calculate various scenarios. These scenarios took a wide variety of relevant parameters into account, such as gate fee, product price, investment, capacity and biomass concentration during processing. The analyses showed that, potentially, a substantial range of profitable scenarios can arise for the production of chemicals at prices that are in line with market prices.

Follow-up research: further specify business case parameters

These positive results in the context of the Waste2Aromatics project generated sufficient material and enthusiasm for those involved to take the first steps towards a follow-up project. The project activities are designed to improve yields, reduce production costs and boost confidence in the technology by realizing an initial scaling-up step. This project’s final deliverable involves designing a pilot plant for the conversion of waste into furans.

The new project, embedded in the Biorizon roadmap for sugars, will have a close relationship with other projects within Biorizon, in which the semi-finished products created here will be processed further into biobased building blocks and, ultimately, into bio-aromatics.

Biobased aromatics offer profitable and sustainable prospects for the chemical industry

Aromatics are one of the main raw materials used by the chemical industry. Aromatics are currently extracted from oil, which leads to the emission of CO2. The Biorizon Shared Research Center, initiated by TNO, VITO and Green Chemistry Campus, develops technologies to extract aromatics from plant residues. This reduces dependency on oil, leads to lower CO2 emissions, and provides profitable and sustainable prospects for the chemical industry and the supply industry.

More information

- Further details about Biorizon: www.biorizon.eu

- Join the Biorizon Community: www.biorizon.eu/community

- Download the comprehensive management summary with the most important results of the Waste2Aromatics project including graphics in the Biorizon Community Library: www.biorizon.eu/community/library

- For more information about (participation in) the Waste2Aromatics follow-up project or Biorizon please contact Monique Wekking (+31 (0)6 46 84 73 58).